Hours: Monday – Friday, 7:30 a.m. to 4 p.m.

Recovery Superintendent: Nick Paul

The City of Columbia Material Recovery Facility is where recycled material gets sorted, compressed, and shipped to a processing facility. This facility operates as a dual-stream recycling system.

The general public may bring separated cardboard, newspaper, office paper, and aluminum containers to the facility at no charge during normal working hours. Other recyclable materials may be brought to the facility for various charges (based upon material type). For small quantities of recyclable material, the public is encouraged to use the Recycling Drop-off Centers conveniently located throughout the city.

How it Works

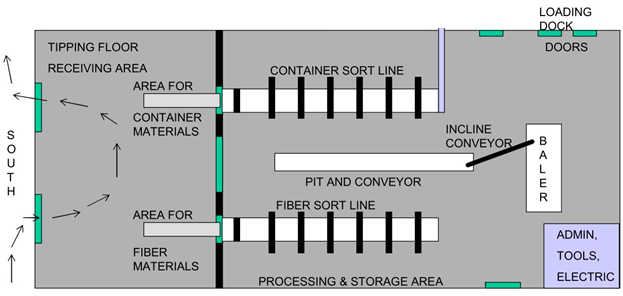

Recycling collection vehicles unload material onto the tipping floor using two gates on the south wall of the facility. Bags of shredded paper are immediately removed and placed into a bunker on east wall of the tipping floor. Cardboard-only compactors are unloaded, and the material is pushed into a pile near the west wall of the tipping floor. All other collection vehicles unload recycled materials near the middle of the tipping floor where mixed fibers are deposited at the east conveyor line and mixed (commingled) containers are moved to the west conveyor line.

The mixed fiber line has 1-2 workers separating bulky cardboard from other mixed fibers as they are placed on the conveyor line. The mixed fiber materials are then separated manually on the fiber sort line. The mixed container line has 1-2 workers who break open the blue recycling bags from curbside collection to deposit loose material onto the conveyor line. The mixed containers are manually separated for #1 plastics, #2 plastics, and #3-7 plastics. The metal food cans are separated manually and by the use of magnets. Aluminum cans are sorted toward the end of the line using an eddy current separator. The remaining material on the conveyor line, glass, drops onto a smaller conveyor belt that exits the building and drops into a bunker on the exterior west wall.

Once the bunkers of sorted material are full, materials are moved to a centralized pit and conveyor line to be baled on the north end of the facility. The finished bales are then stacked by material type and shipped to a processing facility or manufacturer.